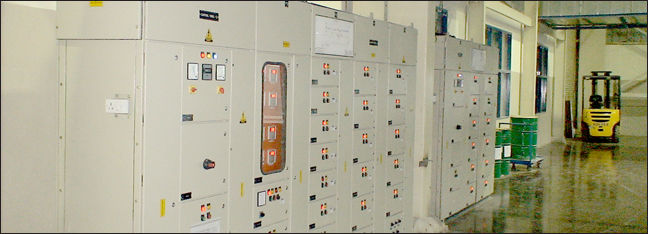

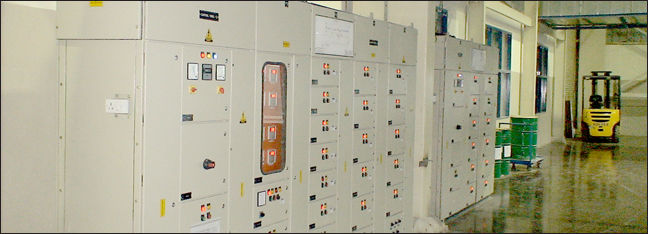

The Control Panels are very critical in paint-shops. The operations, efficiency and Safety of the Paint-shop depend on the Control panel design. Crescent provides following type of Panels.

- The conventional type of panels with contactors and relays most commonly used in the industry. We provide all the safety like HRC fuses/MCB and Relay protection. The electric circuits are inter locked/connected for small automation. Mimics may also be provided on the panels for better process display and Controls.

- PLC based control panels which perform control functions through modular input and output (I/O) modules. The modularity of PLC allows the user to combine generic I/O modules with a suitable controller to form a control system specific to his needs.

Input devices and output devices of the process are connected to the PLC and the control program is entered into the PLC memory.

-

Touch Screen Panels : Crescent plants can be

provided with touch screen Control panels where as the complete panel and its process details can

be operated / controlled from the touch screen

provided on the PLC panel . With these plans plant process can be automated to save on fuel and energy.

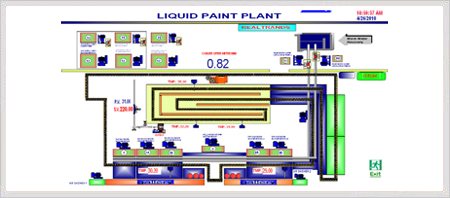

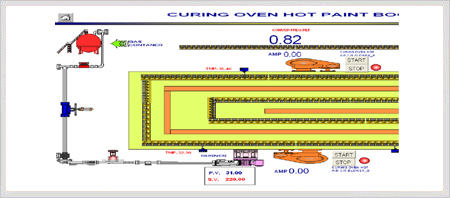

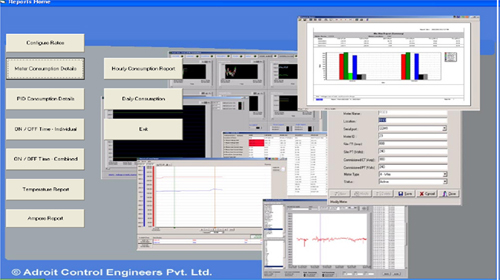

SCADA Based Control Panels : Crescent now offers SCADA- Supervisory Controls and Data Aquision based control Panels for better controls of the Plant . The supervisor or the Paintshop manager can control the complete plant from a remote location. Different datas can be collected and the reports can be obtained as desired for better process controls, low maintenance and automation of the system. Different reports like current of various critical motors, Conveyor speed and oven/booth temperatures at a given point of time, fuel consumption with productivity etc. can be tabulated with these panels.

Advantages of SCADA

- Automated Centralized Control data logging and reporting with Alarm Control systems.

- Lesser maintenance and user friendly Mimic Process visualization

- Output derivations for timely predictive maintenance avoiding break-down times.